PCB vs PCBA: What's the Difference

If you are interested in electronics, then you might have come across these two abbreviations, PCB and PCBA. These two abbreviations are used interchangeably, but they are very different from each other. So what's the difference between these two terms?

PCB-Printed circuit Board

PCB simply stands for the Printed Circuit board. It is a board that connects electronic components electrically using things such as pads and conductive traces. On top of that, other features can be etched from a copper foil and then laminated on a non-conductive substrate made from the resin material of glass epoxy.

PCBs can be divided into many signal layers i.e., 4, 6, or 8. However, four and 6-layers are the ones that are the most common. A PCB pattern can come in different designs. E.g., a printed circuit, a printed component, or a combination of the two.

The alternatives of PCBs are point to point construction, and wire wrap but these are rarely used. A lot of effort is required to layout the circuit on a PCB. However, this process can be automated for mass production. The circuit board substrate is usually made from dielectric composite materials. These materials can be epoxy resin and reinforcement of other materials such as glass fibers, or paper.

At first, these boards were designed manually on a clear mylar sheet by creating a photomask. However, modern PCBs are designed using dedicated software.

Uses of a PCB

A PCB is mostly customized and used to manufacture electric devices such as cameras, TVs, Radio's, cellphones, and some computer parts. For example, graphic cards and motherboards. On top of that, PCBs can be used to manufacture:

1.Medical equipment,

2.Some industrial machinery,

3.In the automotive industry

4.Lighting equipment

A PCB is a vital structure for most appliances because it supports many electronic components and serves them with electricity at the same time. Features that make a PCB unique are:

1.PCB's manufacturing process can be automated

2.PCB is lightweight and small, yet it can handle high-density wiring

3.Inspection, debugging or maintenance of equipment is easy due to the PCB's repeatability and consistency

Types of PCB

1.Single-layer PCB

You can also refer to it as a single-sided PCB. It's the most common and simplest form that you can find in electronics. Reason being that it's easy to produce since it has a simple design. The single-layer PCB only contains a single layer of conducting material, which is mostly copper. The PCB can be protected from oxidation by the use of a sheet of solder mask. Besides, a single layer PCB is the one that is mostly used in bulk production for devices like radio, calculators, and printers

2.Double-layer PCB

Double-layer PCB is also commonly referred to as double-sided PCB. It comes with a layer of conducting material that is applied in both the top and the bottom of the board. The main advantage of a double-layer PCB over a single layer is that it has a reduced size and enhanced flexibility hence making the circuit compact. The double-sided board is mostly used in phones, industrial controls, amplifiers, ups systems, HVAC applications, converters, and power monitoring units.

3.Multi-layer PCB

Multilayer PCB comes with more than two conductive layers. In addition, this board is designed to prevent excess heat from damaging it. This is usually done by sandwiching glue between the insulations. Multi-layer PCBs are mostly done in complex systems such as GPS technology, satellite systems, medical equipment, data storage equipment, and file servers.

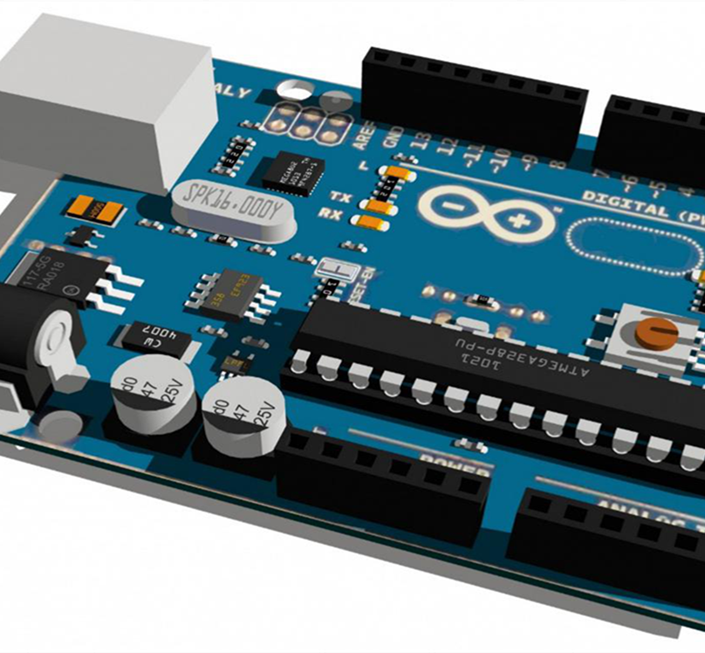

PCBA- Printed Circuit Board Assembly

A PCBA refers to the process of populating the PCB board with various components such as capacitors, integrated circuits, transformers, resistors, or any other parts that are required depending on its uses. You can also refer to it as a process of passing the PCB through surface mounted technology and plated through-hole. These two processes are essential because they are that allow the components to be soldered on the blank board. Some of these processes include reflow soldering, solder paste printing, and component placement.

Components of PCBA

An empty PCB board must be populated with electric components so that it can form a working PCBA. Through-hole technology is used to mount these components on holes. Also, these holes must be surrounded by conductive pads so as the whole board can function. The pins of the components are aligned on one side of the component using SMT, while the parts are anchored on the opposite side.

The two main ways for integrating components on a PCB are DIP and SMT. In DIP, you need to drill holes so that the pin of the component that you are adding can be inserted inside that hole. However, SMT (Surface mounted technology) requires a placement machine

You can inspect it visually with power off or using an inspection tool such as an automated optical. Still, with the power of you can carry out a signature analysis. Also, you can turn the power on and perform in-circuit testing. Lastly, you can carry out a functional test that will confirm whether your board functions as intended.

The differences

The main difference is that PCB is the bare board, while PCBA is the process of refilling the board with electronic components such as integrated circuits and capacitors. After printing solder paste and mounting the components, you will get a PCBA (Printed circuit Assembly). In order to establish a mechanical connection, reflow furnace heating is carried out.

A PCB cannot be used in the manufacture of electronic devices without the components being implanted. So a PCBA is the final product that is integrated during the production of these devices. However, they are passed through inspection and a rectification process so that all the errors are rectified. A PCBA is made from a finished circuit board. So without a PCB, then you cannot have a PCBA.

Final thoughts

PCB is simply the circuit board, while PCBA is a finished circuit board. These two abbreviations are closely related because they share one thing in common i.e., the circuit board. But when all the components are mounted on the PCB, then it becomes a PCBA. And it can now be used to make an electronic device.