| Number of layers | 4-16 layers |

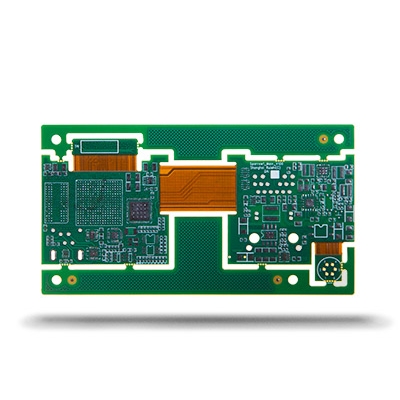

| Technology highlights | Mixed materials including RF and high speed, standard FR-4, polyimide flex. Adhesiveless or adhesive based polyimide flex constructions, with cover coat or flexible solder mask materials. |

| Bending performance | Based on the specific design, the bend performance can range from a basic 90 °bend to fit to a full dynamic flex with 360° range of motion in the flex tail that will withstand continuous cycles throughout the product life. |

| Bend features | Bend radius controls the flexibility of the flex portion of the board. The thinner the material the lower the bend radius and the more flexible the flex section. |

| Materials | RA copper, HTE copper, FR-4, polyimide, adhesive |

| Copper weights (finished) | ½ ounce, 1 ounce, 2 ounce, 3 ounce |

| Minimum track and gap | 0.075mm / 0.075mm |

| PCB thickness | 0.4mm to 3mm |

| PCB thickness in flex section | 0.05mm to 0.8mm |

| Maxmimum dimensions | 457mm to 610mm |

| Surface finishes available | ENIG, OSP Immersion tin, Immersion silver |

| Minimum mechanical drill | 0.20mm |